Large Projects Upcoming in Palm Beach Gardens 2019

Monday, September 19 through Saturday, September 25, 2022

Update May 1, 2022: The resident spots are sold out. I have 2 places remaining if you don't require a room or make your own arrangements. I'm happy to assist with possible hotels/houses for rent. I'm also maintaining a waiting list so let me know if you are interested. This sold much faster than expected.

What could be better than 6 glorious days of uninterrupted sewing in the picturesque town of Bristol, Rhode Island. Join me for expert help creating your custom design. This is a great opportunity to work on a French jacket, tackle lace, refine fitting issues or work on an unfamiliar style. We'll work from 9 AM to about 5:30 PM but you will have 24 hour access to the studio in case you want to work overtime.

Our home for the week will be a lovely 4 bedroom house with detached finished garage which will be setup as a spacious sewing studio. There will be a large cutting table, individual work spaces as well as professional pressing equipment. Bring your own sewing machine or borrow one if you prefer. Let me know you need a machine when registering.

While investigating the area, I discovered that Apple Annie Fabrics, owned by Anne Kendall is a 15 minute drive from our studio. Anne and I spent the morning chatting sewing and I received a tour of her well stocked store.

In addition to fabrics she has a large selection of thread, notions, patterns, etc. so not to worry if you forget to bring a necessary item. I also loved her inspiration wall of fashion.

I also spotted a wonderful bolt of boucle which I'll be using for an upcoming custom trim class. This particular fabric combines black with deep rose threads; I'm envisioning multiple variations using coordinating yarns along with the fabric fibers.

Cost of the 6 day class plus 7 nights accommodations is $2250. Class without room is $1500. There will be welcome drinks/snacks on Sunday 9/18 plus 2 dinners: an authentic New England lobster boil and Portuguese style grilled feast. All are welcome to join us for dinner.

For a link to registration and additional information click here.

Also complete the contact form. Please note that all participants are required to have received a COVID vaccination.

Any questions, please email me at MF953@aol.com or mary@cloningcouture.com

Registration is open for classes in Palm Beach Gardens. Join the 7 day French jacket class from Monday, November 7 through Sunday November 13, 2022. These jackets involve considerable hand sewing and do take time, so expanding the class to 7 days made sense.

What is unique about this class? We will start with fine tuning the fit of your jacket toile. Detailed instructions will be sent several weeks prior to class.

Vogue 7975 is often used as the basis for a French jacket. It is easy to change the jacket's length, neckline, sleeve and front closure. The pattern has princess seams ending in the shoulder which simplifies many fitting issues. Curvy figures need more shaping which can result in any horizontal stripe in the fabric to be mismatched along the upper part of the front princess seam. This photo shows the difference.

The right side (right side of photo) of this sample has been cut and sewn according to the pattern. For the left side, I've made some simple changes to the pattern and shaped the front side section with a steam iron. Note how the horizontal lines in the weave carry across the upper chest uninterrupted.

We will examine techniques to eliminate darts. For this sample, I wanted a very curvy figure, easily accomplished by a bra filled out with extra padding. It's easy to achieve the look on a small busted model but harder when dealing with more curves.

The pronounced curves of this figure required additional shaping which could have been accomplished by adding a dart either from armhole to bust or side seam to bust.

Either dart placement isn't ideal and will create unnecessary bulk. Fortunately most boucle fabric is pliable and can be molded with steam. Any distortion in the weave is hidden under the arm and a better solution than darts.

A few patterns have the classic three piece sleeve. Vogue 7975 has a standard two piece sleeve. It's not difficult to convert the pattern. This method can be used on any sleeve.

Learn how to customize the look of a basic pattern. The neckline is easily converted to a stand collar, round or V-neck.

Coco Chanel said, "never a button without a buttonhole." Machine buttonholes are an option but handworked buttonholes are a true couture finish. Loosely woven boucle fabric isn't the easiest to work with and mastering buttonholes does take practice. There are a few tips and tricks that make the finished result more professional.

Trims are the final embellishment. Shopping for pre-made trim can be difficult. You rarely find something that's the perfect color, width and texture. Often trims are rigid and difficult to navigate curves and corners. Creating your own trim using fibers from the fabric and coordinating yarn isn't difficult.

November dates not convenient? Another Couture Sewing Class is scheduled from Monday, January 16 through Saturday, January 21, 2023. This class isn't strictly for French jacket construction but you can certainly work on one. It's a perfect opportunity finish (or make significant progress) on a previously started jacket. Work on anything you like. Maybe you're hesitant to work on tricky fabric or an unfamiliar style? Take advantage of expert help with planning and executing your project.

Register by clicking on "Classes" from the main menu. Any questions email me: mf953@aol.com

I'm presenting a couture trim class with the ASG (American Sewing Guild) Atlanta chapter on Friday March 25 and Friday April 1. This is an 8 hour class (split into 2 four hour sessions) which will be presented via internet on Zoom. Both sessions will run 1:30 to 5:30 PM EST. One fee includes both sessions. The class fee also includes the trim kit so you will be able to create the trims along with me. This class was designed exclusively for the Atlanta ASG and open only to their members. The class has a few available openings and I have permission from the Atlanta group to open the remaining spots to my readers.

This trim from a Chanel jacket has always intrigued me and I FINALLY figured out a way to replicate it. It will be demonstrated in this class along with numerous other techniques including Kumihimo braiding.

If you're interested, go to http://www.asgatlanta.org and register. The class will not be recorded so you will need to be available during class time. Registration will close on March 19 to allow time for your trim kit to be shipped to you.

There will also be a class on couture custom sleeves on Saturday, March 26 from 1:00 PM to 2:30 PM EST if you're interested.

I will be offering additional trim classes later this spring and summer on my site. Thanks for reading.

A distinctive feature of many French (Chanel) style jackets is the iconic three piece sleeve. Vogue 7975 is a favorite starting pattern for many; however the sleeve is a standard two piece. I'll go through my method for converting the pattern from a two to three piece sleeve.

First, trace the pattern onto translucent pattern paper. Eliminate the seam allowances. It's much easier to alter patterns when you aren't dealing with seam allowances. Make changes to the pattern, then add seam allowances back if you are more comfortable working with patterns which have seam allowances included. Include the marks indicating underarm and shoulder points as well as grain lines. Mark the front and back of the sleeve cap to eliminate confusion.

Working on a grain board/cutting mat makes it easy to keep the pattern properly aligned. Arrange the pattern pieces as shown with grain lines parallel to each other and seam lines just touching along the back armseye seam. Tape or weight the paper so it doesn't shift.

Using a second sheet of pattern paper large enough for the entire sleeve, trace the shape of the sleeve cap from the underarm point to shoulder point, continuing through the front armseye seam. Mark the underarm and shoulder points. Also draw a line at a 90 degree angle to the grain lines intersecting the underarm point. This line represents the biceps width.

Move the undersleeve pattern to the front, arrange grain lines parallel to each other and trace the remainder of the arsmeye seam to the underarm point.

Also shift the grainline on the upper sleeve section so it is in line with the shoulder point. Connect underarm points with a horizontal line which should be perpendicular to the grainline.

Your draft should look like this:

Draw dashed lines from the underarm points to the hem. They will be parallel to the grainline and be the same distance apart as the biceps width. Measure the distance along the biceps line from back to the new grainline (intersects the shoulder). Measure distance from grainline to front underarm point. Compare the measurements. I'm working with a size 10 pattern. The back measures 7"; front measures 6.5". Therefore the grainline is offset 1/2" from the midpoint of the front and back underarms. If your pattern size varies slightly, then use the measurements from your size. The additional curves which are mirror images of the armseye seam will be covered in upcoming steps.

Now calculate the sleeve taper from underarm to wrist. Measure the wrist on front and back sleeve sections and add them together for total sleeve wrist measurement. Size 10 is 9 inches. I want to offset the wrist by the same amount of the biceps. Divide 9 by 2 equals 4.5". Add 1/4" to 4.5" for 4.75" back wrist. Subtract 1/4" from 4.5" for 4.25" front wrist. 4.75" plus 4.25" equals 9" so the total matches amount measured in the previous step.

Also draw in the elbow line. There are various methods for determining the elbow placement. You can measure from underarm to elbow. If you're not sure, divide the underarm seam in half. Place the elbow about one inch higher than the midpoint.

Where the elbow and underarm seam intersect on the sleeve back, mark a point 1/4" wider than the elbow. Measure the distance from this point to the center grainline. Divide this distance in half (should be about 3 inches). Measure 3/4" down from the elbow line. Draw a line from this point to the halfway point just plotted, forming a dart at the elbow.

At the back wrist, mark a point 3/4" towards the center and 3/4" below the wrist hem. Connect the lower elbow dart leg to this point. The wrist will be shortened 3/4" so 3/4" needs to be added to the front underarm. Draw a line from the elbow to a point 3/4" to the right of the original seam.

Connect the front and back wrist hem with a smooth curve. Also shift the center grainline from elbow line to wrist 3/4" as shown.

Fold the pattern vertically, matching back underarm to grainline. Turn the pattern over with underside up. You will see the armseye curve. Using a red pencil, trace the curve as shown. Repeat for the front.

Now you will draft the narrow under-sleeve. Starting at the underarm, measure 1 and 1/4" to left of grainline; 1 and 1/8" to the right. Move to the elbow line. Measure 1 and 1/4" to the left, 1" to the right. Move to the wrist. Mark 1 and 1/8" left of the angled line, 7/8" to the right. Connect the points to form the under-sleeve. Shown in green.

The under-sleeve now needs to be removed from the outer edges of the back and front sleeve. Measure towards the center of the sleeve on both back and front, the same amounts that were used to draft the under-sleeve. Back underarm, measure in 1 and 1/4", front underarm 1 and 1/8" towards center. Elbow line 1 and 1/4" along the back, 1" along the front. Wrist 1 and 1/8 at back, 7/8" at front.

This is the right sleeve. The under-sleeve as drafted is for the left sleeve. To create a right side pattern, flip the sleeve draft over and trace the under-sleeve onto pattern paper.

Flip the draft back to the right side and cut the back and front sleeve sections as shown. The elbow dart won't be sewn as a dart. When constructing the sleeve, you will ease about two inches either side of the dart, drawing up the excess length to match the under-sleeve seam.

Shorten the front sleeve seam about 1/4" and redraw the wrist hem curve. The front seam will be stretched during construction to produce a better curve in the finished sleeve. Yes, the front sleeve seam that attaches to the under-sleeve will be slightly shorter than the corresponding seam on the under-sleeve pattern.

If you want to add sleeve vent for buttons/ trim, tape extensions onto the pattern. I used 1 and 1/2" wide and 4" long. If you want longer vents for more buttons, then just make the vent longer.

The grainline of the undersleeve can be changed to bias providing a little more flexibility in the sleeve.

Want to add a stand collar to your French jacket but don't have a pattern? Here are easy directions for drafting your own. Two jackets to which I've added a stand collar.

I used Vogue 7975 which has a high round neck. To draft the collar measure the pattern from center back to the shoulder seam. Note that measurement. Then measure from shoulder seam to center front.

Draw lines at right angles to each other in the lower left corner of pattern paper.

Mark the intersection of the two lines CB (center back). Measure to the right of CB the length of CB to shoulder seam as measured on the jacket pattern. Mine was 3 5/8 inches. Be sure to measure the seam line, NOT cut edge. Mark shoulder point.

From the shoulder point measure towards the right the distance from shoulder to center front on the jacket pattern. Mine was 4 1/2 inches. Mark the point as CF (center front).

Draw a line 3/4 inch long up from CF.

Using a French curve draw a smooth curve from the shoulder point to the point 3/4 inch above the bottom line.

Decide how wide you want the collar. I used 1 1/4 inches. Draw a line parallel to the bottom line.

You can leave the top edge square or round off the corner. I use a circle template to determine how I want the curve shaped.

Finished collar pattern. This pattern has no seam allowances. I cut it from card stock so it's sturdier and can be used as a template for pressing the seam allowances under.

The collar is slightly curved. Rather than cutting the collar so that the horizontal weave of the fabric is interrupted, the couture way of working is to cut a straight strip of fabric on the crossgrain. The fabric is shaped with steam into a curve to match the collar pattern. Position the fabric wrong side up with the neckline seam away from you. Using a steam iron, stretch the upper edge and ease the bottom edge to create a curved strip of fabric. The curve of fabric should match the curve of the collar pattern.

Thread trace the seam lines. To make the curved edges identical use the card stock template to press seam allowances under. A machine basting stitch along the curve can help ease in fullness. Add either fusible or sew-in interfacing. I used fusible for this demo.

Press the seam allowances along the outer edge of the collar under. Don't press the seam which will join the collar to the jacket. The template will ensure the curved ends are identical. The inside of the collar can be either self fabric or lining. I've used self fabric for this inside collar. Attach the outer collar to the jacket along the neckline. Fell stitch the turned under edges of outer and inner collar together.

Next up will be transforming the two piece sleeve of Vogue 7975 into a three piece.

Thank you to all those who registered. The March 1 class sold out within the first day so I'm offering the same class one week later. You can sign up for the March 8 class here. Same time: 5-7:30 PM EST.

UPDATE: The link wasn't working but it should be fixed. Class half-filled so it did work for some. You can also navigate to the class by going to "Shop" on main page, open Catalog and go to class. Thanks all who alerted me to the problem.

For my readers in Australia: Australia is only accepting Global Express Mail which is more expensive than the Global Priority offered in the shipping options. I've sent an email to those interested to see if we can find one person/shipping address. I will send a bulk order which that person can then distribute within Australia. Let me know if you are interested and I'll put everyone in touch with each other.

I'm thrilled that so many of my readers are interested in exploring custom trims. See you soon.

To expand my variations of custom trim, I've been experimenting with tubular yarns as well as crocheting with narrow strips of fabric. Many boucles are woven using tubular yarns, such as these two.

I pulled strands of the tubular knit from the fabrics and filled them with bulky wool yarn. Wool yarn works better than acrylic or cotton as it is lofty yet soft and flexible.

The tubes can be woven through a crochet base or braided. A technique for tubes of fabric used as braided trim here. This boucle contained gold tubular yarn as well as multiple other fibers and lent itself to several variations of trim.

You can also find tubular yarns put up in rolls or skeins. Any time I find metallic silver or gold I stock up, as gold/silver compliment many fabrics.

Another interesting technique uses narrow strips of silk georgette fabric to work a chain stitch along the edge of trim. This is a version created from a combination of ivory wool yarn combined with fibers pulled from fabric yardage and edged with a chain stitch of silk georgette. The bias edge of silk frays just enough to create a soft textured finish.

Join me on Tuesday, March 1, from 5-7:30 PM (Eastern standard time) for a hands-on virtual workshop in which we'll create multiple variations of trim. Sign up (PLEASE NOTE: This link is for the March 8 class. The March 1 class is sold out) through the Cloning Couture Shop. The class is limited to 20 participants. A kit containing crochet hooks, sample boucle fabric plus assorted yarns is available here or you can source your own materials. The class is held via Zoom and will be recorded so if you can't participate live, the recording will be available. You can also download and re-watch the class as often as you wish.

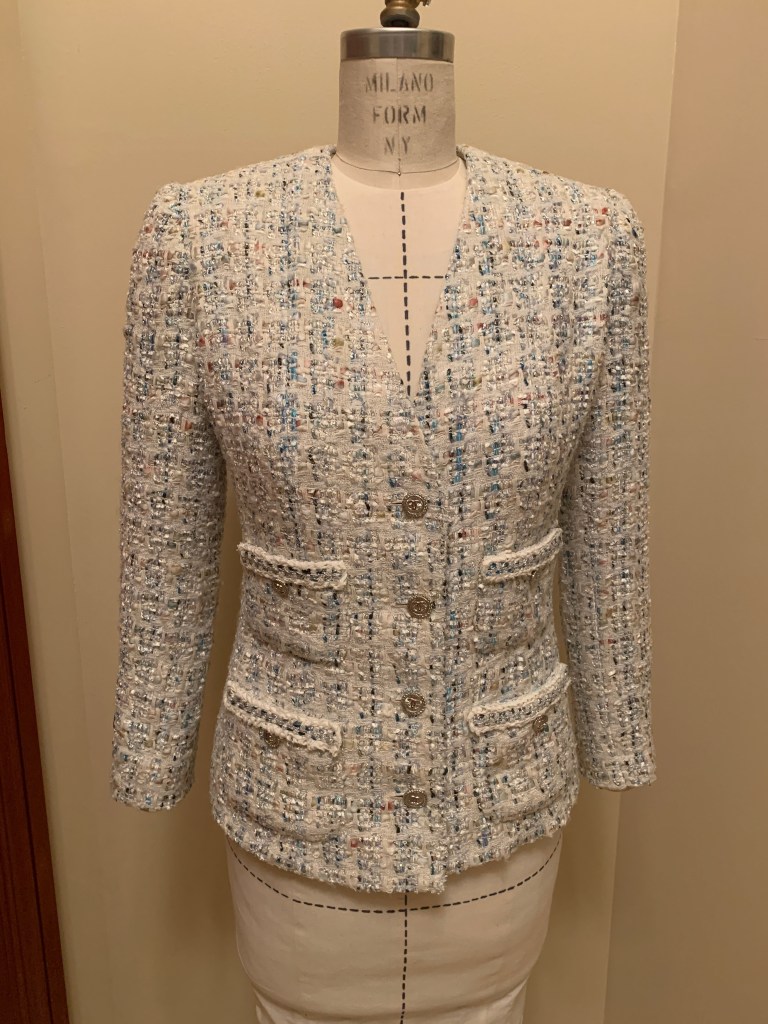

Here is the jacket I used for demonstration in a recent French Jacket Class. The trim utilizes fibers pulled from the yardage plus silk georgette used as yarn.

Plus a couple of closeup shots of the trim.

Enjoy creating your own customized trims.

In my recent moulage/dressform class, students used everything from a custom made full body form from Wolf to a display form found at Hobby Lobby. Evidence that you can get almost anything that resembles a body to work.

We ripped the existing base off the display form and replaced it with a wooden dowel. The dowel fit into a sturdy cast iron base and was a huge improvement over the rickety wooden one. Class begins with taking about 25 body measurements. We then draft a moulage, or mold, of the body. The drafted moulage pattern is cut from sturdy muslin and tested on the body. Fit adjustments are made and transferred back to the paper pattern. When all looks good, we cut the final dressform cover from heavier muslin and do one last fit check.

The muslin cover is draped onto the form. Placement and amount of padding is assessed and we start padding the form to fill out the cover. Depending on where padding is needed, I'll suggest using various bust cups, cotton quilt batting or polyester batting. The poly batting is steamed to compress and firm up the shape. The display form fit her neck and shoulders surprisingly well. Bust, waist and hips can all be customized with layers of compressed batting.

At the opposite end of the dressform spectrum is a custom made full body form from Wolf. This student had wrestled with fitting problems for years and tried everything from body scan versions to this custom model but nothing seemed to address a key fit issue.

She had already drafted a custom cover to fine tune the fit. It needed firmer padding and a key adjustment for a high hip. After drafting the moulage it was test fit and elastic tied around the waist to pinpoint the fit issue. The right hip significantly higher causing skirts and pants to ride up on the right side. Notice the position of the waist when her back draft is laid out on a grid. Lowering the hem on that side really doesn't fix the problem.

We carefully marked the dressform cover and added padding to duplicate the hip contours. The finished form is a much better fitting aid with balance lines correctly placed.

We tested the fit using several of her dresses. The new mannequin pinpointed the need for a slight full bust alteration to remove the drag lines around the bust dart. The moulage patter is used to create a custom sloper or basic pattern which can be used as the basis for drafting additional styles and correcting commercial patterns.

The next custom moulage/custom dressform class will be held January 10, 11 and 12 in Palm Beach Gardens, FL. For more information: Dressform Class

I recently had the pleasure of working with a delightful bride and her mother. She had chosen a simple, yet dramatic, gown of heavy white silk crepe. With the fall wedding planned to take place outside in a vineyard, she envisioned a coat to compliment the gown.

I felt attempting to match fabrics was risky. Fortunately, as with most made-to-order gowns, the bride's mom was able to order matching fabric from the bridal manufacturer. Fashion illustration isn't my strength but this sketch shows the gown and accompanying coat.

Ordinarily I would start with body measurements to create a custom drafted pattern. Anyone who has done bridal work, knows how much measurements and the bustline can change depending on undergarments. Therefore, the coat needed to be drafted according to measurements taken over the fitted gown. After gown alterations were completed, I put the gown on a mannequin and started drafting the coat.

Here's the finished pattern with princess seams moved into the armseye and neckline extending from shoulder to waistline. Long slim sleeves will be added. The skirt is quite flared to match the fullness of the gown.

I absolutely LOVE my cutting table. Covered in canvas, 60 inches wide with vertical grain lines in black, horizontal lines in red and diagonals in green. It makes doing layouts for long gowns so easy. It also worked well for aligning the veil.

The bride planned to wear this lovely heirloom veil of intricate lace which was a perfect compliment to the solid crepe gown. We noticed a few small tears in the veil and I felt that attempting to repair them would have resulted in noticeable stitches. The decision was made to back the entire veil with soft tulle. The underlying layer of new tulle would stabilize the fragile netting.

Working on ivory tulle on an ivory canvas background makes seeing your work next to impossible. I often do these projects over a layer of black canvas which makes the work much, much easier on the eyes. The detail of this lace was just amazing. Machine stitching would have been a disaster, so the supporting tulle was hand stitched in place, then trimmed away from the edge.

This fall was a crazy bridal season and I forgot to take process photos during the construction. I did receive these. Perfect for a late fall outdoor wedding. Congratulations! I loved working with you.

Having a dressform that duplicates the figure you're sewing for makes the process SO much easier! Your model stands perfectly still for hours and doesn't mind being stuck over and over with pins. She also eliminates the need for multiple in-person fittings, which was a life-saver during the worst days of COVID.

Here's my process to create this gown which made it's debut at the recent opening of Carnegie Hall in NYC. The design was inspired by this exquisite pleated tulle from Mendel Goldberg Fabrics.

I start by draping the fabric on the mannequin and experimenting with how it will drape and best positioning of the design. This fabric was meant to have a full skirt with one seam at center back. Additional seaming would have interrupted the flow of fabric. I also secured a full tulle underskirt to the form to get a clear vision of how much fabric was needed for the skirt.

The bodice looked best using the denser side of the lame portion at the neck and semi sheer section along the waist. I tried two versions, one using the sheer tulle for the back, a second option with the gold. I decided on the first option as the sheer back seemed more interesting; the gold back was too much gold. With the skirt basted into a grosgrain ribbon waistband, the design was complete.

Pattern work for front bodice: left photo is 1/2 of front which will be cut with fold at center front. In order to cut it with the neck gathered fuller, I drew 6 evenly spaced lines from neck to waist, left the pattern attached at the waist and spread out along the neck edge until the side seam was parallel to center front. The altered pattern was traced onto a new sheet of paper.

Left photo shows altered pattern on the tulle. Neck is at the top, waist at bottom with center fold at the right edge. Placed on the form, checked for accuracy and waistline thread traced. The back was cut from sheer portion of the tulle with pleating running vertically.

Basted everything together for a final fit check. I opted to finish the neckline with a stand collar of gathered tulle cut from the gold portion. A zipper in both underskirt and tulle allows the outer layer of tulle to hang freely; attaching it to the inner layers resulted in unattractive pulling. An inner waistband of grosgrain ribbon holds everything in place and supports the weight of the skirt.

Final try-on in the studio; fit was perfect on the first go thanks to a custom form and worn for gala night out.

Source: https://cloningcouture.com/

0 Response to "Large Projects Upcoming in Palm Beach Gardens 2019"

Post a Comment